The Complete Guide to Draught Proofing Your Timber Sash Windows

Draught proofing timber sash windows is one of the most effective ways to improve your home’s energy efficiency whilst preserving the character and charm of these traditional architectural features. Many homeowners with period properties struggle with cold draughts, high heating bills, and uncomfortable living spaces during the winter months, often believing that these issues are simply the price of living with historic windows.

However, with the right approach to draught proofing, it’s entirely possible to achieve modern standards of thermal comfort whilst maintaining the authentic appearance and operation of your timber sash windows. Professional draught proofing can reduce heat loss by up to 50%, significantly lowering energy bills and creating a more comfortable living environment throughout the year.

Understanding the various draught proofing options available, from simple DIY solutions to comprehensive professional systems, will help you make informed decisions about improving your windows’ performance. Whether you’re dealing with minor draught issues or significant air leakage, there are solutions suitable for every situation and budget.

Understanding Why Timber Sash Windows Create Draughts

Before exploring draught proofing solutions, it’s essential to understand why timber sash windows are particularly prone to air leakage. The traditional design of sash windows, whilst ingenious in its simplicity, creates multiple potential points where air can infiltrate your home.

The sliding mechanism that allows sashes to move up and down requires clearances between the moving parts and the frame. Over time, these clearances can increase due to wear, paint build-up removal, or timber shrinkage, creating gaps that allow air to pass through. The meeting rails where the upper and lower sashes come together represent another significant source of air leakage, particularly if they’ve warped or if the original sealing mechanisms have deteriorated.

Timber is a natural material that expands and contracts with changes in temperature and humidity. This movement, whilst generally beneficial for the long-term health of the windows, can create seasonal variations in gap sizes. During dry periods, timber may shrink, increasing gaps, whilst humid conditions can cause swelling that temporarily improves sealing but may create operational problems.

The age of many timber sash windows means they were constructed before modern understanding of thermal performance and air tightness. Original construction methods prioritised durability and functionality over energy efficiency, as fuel costs were relatively low and environmental concerns were not yet prominent considerations in building design.

Types of Draught Proofing Solutions

Modern draught proofing for timber sash windows encompasses a range of solutions, from simple temporary measures to comprehensive professional systems that can transform the performance of your windows whilst preserving their historic character.

Self-Adhesive Weatherstrips represent the most accessible entry point for homeowners looking to improve their windows’ draught proofing. These products, typically made from foam, rubber, or brush pile materials, can be applied to window frames to create seals against air infiltration. Foam strips are the most economical option and can provide immediate improvement, though they may not be suitable for all situations and typically have a shorter lifespan than other solutions.

Rubber weatherstrips offer better durability and sealing performance than foam alternatives. They’re available in various profiles to suit different gap sizes and can accommodate the movement of timber windows more effectively. However, they require careful selection to ensure compatibility with your specific window design and operation.

Brush Pile Weatherstrips are considered among the most effective solutions for sash windows. These consist of a plastic or metal carrier strip with fine synthetic bristles that create a flexible seal whilst allowing smooth operation of the sashes. The bristles can compress to accommodate variations in gap sizes and provide excellent sealing performance without impeding window operation.

Professional Draught Proofing Systems represent the gold standard for sash window thermal improvement. These systems typically involve the installation of precision-engineered sealing strips that are routed into the window frame and sashes, creating virtually invisible seals that don’t affect the window’s appearance or operation. Professional systems often include specialised meeting rail seals and can achieve air tightness levels comparable to modern windows.

DIY Draught Proofing: A Step-by-Step Approach

For homeowners comfortable with basic DIY tasks, implementing draught proofing measures can be a rewarding project that delivers immediate benefits. The key to successful DIY draught proofing lies in careful preparation, appropriate material selection, and methodical application.

Begin by conducting a thorough assessment of your windows to identify all sources of air leakage. On a windy day, use a lit candle or incense stick to detect draughts around the window perimeter, paying particular attention to the meeting rails, sash edges, and the junction between the window frame and wall. Mark all problem areas with masking tape to ensure you address every source of air infiltration.

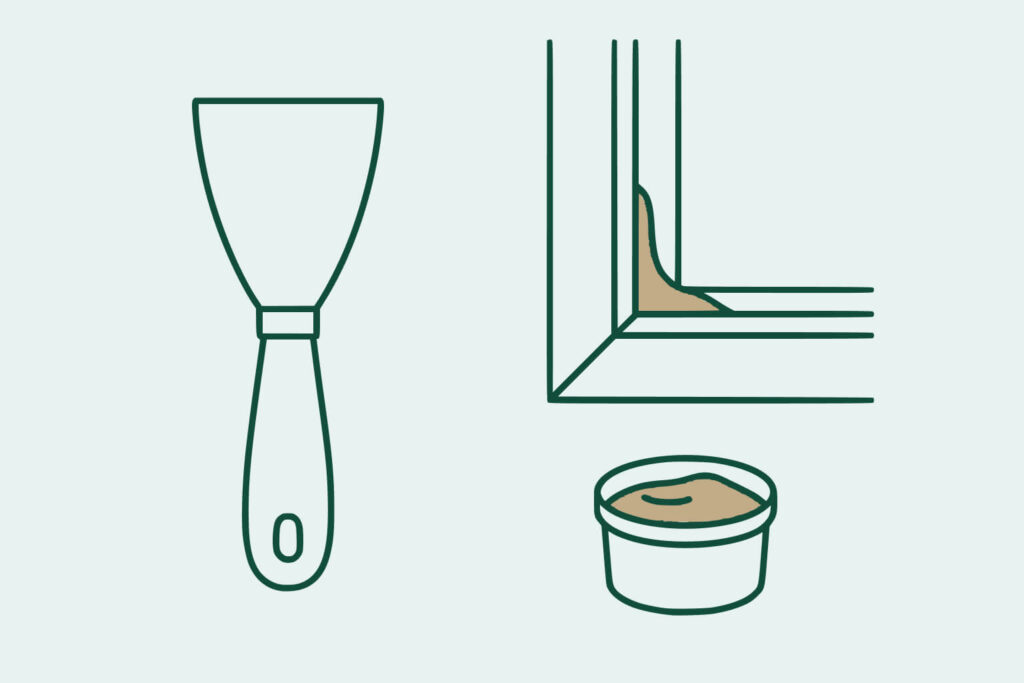

Clean all surfaces thoroughly before applying any draught proofing materials. Remove dirt, old paint flakes, and any existing weatherstripping that may have failed. For self-adhesive products to bond properly, surfaces must be clean, dry, and free from dust or grease. Consider using a degreasing agent on areas that may have been treated with furniture polish or similar products.

Measure all gaps carefully and select appropriate weatherstripping materials. For gaps between 2-4mm, thin foam or rubber strips are usually suitable. Larger gaps may require thicker materials or multiple applications. Remember that timber windows move seasonally, so allow for some variation in gap sizes throughout the year.

Apply weatherstripping systematically, starting with the most significant sources of air leakage. For vertical sash channels, ensure the strips don’t interfere with the window’s operation by testing movement frequently during installation. Pay particular attention to corners where strips meet, as these junctions are potential weak points in the sealing system.

The meeting rails require special attention as they represent one of the most significant sources of air leakage in sash windows. Consider using brush pile strips or specialised meeting rail seals that can accommodate the sliding action whilst maintaining an effective barrier against air infiltration.

Professional Draught Proofing: What to Expect

Professional draught proofing services offer comprehensive solutions that can transform the thermal performance of timber sash windows whilst maintaining their authentic appearance and smooth operation. Understanding what professional installation involves will help you make informed decisions about this investment.

A professional assessment typically begins with a detailed survey of your windows, including measurements of all gaps, evaluation of the window condition, and identification of any underlying issues that might affect draught proofing performance. Experienced installers can identify problems that might not be apparent to homeowners, such as frame distortion or hidden sources of air leakage.

Professional systems often involve routing narrow channels into the window frame and sashes to accommodate precision-engineered sealing strips. This approach creates virtually invisible seals that don’t affect the window’s appearance whilst providing superior sealing performance. The routing process requires specialist tools and expertise to ensure it doesn’t compromise the structural integrity of the timber.

High-quality professional systems typically include multiple sealing points: perimeter seals around the sashes, meeting rail seals where the upper and lower sashes come together, and often additional seals around the glazing. This comprehensive approach addresses all potential sources of air leakage for maximum effectiveness.

Professional installation also typically includes adjustment of the window mechanism to ensure smooth operation after draught proofing. This might involve easing tight spots, adjusting sash cords, or making minor repairs to ensure the windows continue to function properly with the new sealing systems in place.

Cost Considerations and Energy Savings

The cost of draught proofing timber sash windows varies significantly depending on the approach chosen, the number of windows involved, and the complexity of the installation. Understanding the financial implications and potential savings will help you evaluate different options effectively.

DIY draught proofing using self-adhesive weatherstrips typically costs between £10-30 per window, depending on the materials chosen and the size of the windows. This represents an extremely cost-effective approach that can deliver immediate improvements, though the longevity and performance may be limited compared to professional solutions.

Professional draught proofing systems typically cost between £150-400 per window, depending on the system specification and the complexity of the installation. Whilst this represents a significant initial investment, the superior performance and longevity of professional systems often make them more cost-effective in the long term.

The energy savings from effective draught proofing can be substantial. Well-sealed sash windows can reduce heat loss by 30-50%, translating to significant reductions in heating bills. For a typical period property, this might represent annual savings of £200-500, meaning professional draught proofing can pay for itself within 2-5 years through reduced energy costs.

Beyond direct energy savings, draught proofing also improves comfort levels, reduces condensation problems, and can increase property values. The enhanced thermal performance makes rooms more comfortable at lower temperatures, potentially allowing you to reduce thermostat settings without compromising comfort.

Maintenance and Longevity of Draught Proofing Systems

Like all building components, draught proofing systems require periodic maintenance to ensure continued effectiveness. Understanding maintenance requirements will help you protect your investment and ensure long-term performance.

Self-adhesive weatherstrips typically require replacement every 2-5 years, depending on the quality of materials used and exposure conditions. Regular inspection will help identify when replacement is needed – look for signs of compression, tearing, or loss of adhesion. Keeping spare materials on hand allows for prompt replacement when needed.

Professional draught proofing systems are generally more durable, with quality installations lasting 15-25 years or more with proper care. However, they still benefit from periodic inspection and maintenance. Check sealing strips for damage, ensure they remain properly seated in their channels, and clean them regularly to prevent dirt accumulation that might affect performance.

The key to maintaining draught proofing effectiveness is incorporating checks into your regular window maintenance routine. Annual inspection of all sealing components, combined with prompt attention to any issues, will ensure continued performance and maximise the lifespan of your draught proofing investment.

Combining Draught Proofing with Other Improvements

Draught proofing works most effectively when combined with other window improvements and home energy efficiency measures. A holistic approach to thermal performance can deliver superior results compared to addressing individual issues in isolation.

Consider combining draught proofing with glazing improvements, such as upgrading to high-performance putty or installing secondary glazing systems. These measures work synergistically with draught proofing to create a comprehensive thermal barrier.

If your windows require restoration work, this presents an ideal opportunity to incorporate professional draught proofing systems. The access required for restoration work makes draught proofing installation more straightforward and cost-effective.

Home insulation improvements, such as upgrading loft insulation or improving wall insulation, complement window draught proofing by reducing overall heat loss. A comprehensive approach to home energy efficiency typically delivers better results than focusing solely on windows.

Choosing the Right Solution for Your Property

Selecting the most appropriate draught proofing solution depends on various factors, including your budget, the condition of your windows, your DIY capabilities, and your long-term plans for the property.

For properties where you’re planning significant renovation work or window restoration, professional draught proofing systems represent the best long-term investment. The superior performance and longevity justify the higher initial cost, particularly in properties where you plan to remain for many years.

If you’re looking for immediate improvement on a limited budget, high-quality self-adhesive weatherstrips can provide significant benefits at modest cost. This approach is particularly suitable for rental properties or situations where you’re uncertain about long-term plans.

Consider the overall condition of your windows when making decisions. If your windows have significant underlying problems, such as rot or structural issues, address these concerns before investing in draught proofing. Professional assessment can help identify any issues that might affect draught proofing performance.

For homeowners in conservation areas or listed buildings, ensure any draught proofing solutions comply with planning requirements and conservation guidelines. Professional installers experienced with historic buildings can advise on appropriate solutions that meet both performance and conservation requirements.

The Environmental Benefits of Draught Proofing

Beyond the immediate financial benefits, effective draught proofing of timber sash windows contributes significantly to environmental sustainability. Reducing energy consumption through improved thermal performance helps lower carbon emissions and supports broader environmental goals.

Draught proofing existing windows is inherently more sustainable than replacement, as it extends the useful life of existing materials and avoids the environmental impact of manufacturing new windows. This approach aligns with principles of sustainable building practice and heritage conservation.

The reduced energy consumption resulting from effective draught proofing contributes to lower demand on energy infrastructure and reduced carbon emissions from heating systems. For properties heated by gas or oil, this represents a direct reduction in fossil fuel consumption.

By choosing to improve rather than replace timber sash windows, homeowners contribute to the preservation of traditional building skills and materials. This approach supports the continued viability of specialist trades and maintains the character of historic neighbourhoods.

Effective draught proofing represents a win-win solution that delivers immediate comfort and cost benefits whilst contributing to broader environmental and heritage conservation goals. Whether you choose DIY solutions or professional installation, the investment in draught proofing your timber sash windows will pay dividends for years to come.

For expert advice on draught proofing solutions tailored to your specific requirements, consider consulting with professional window specialists who understand the unique challenges and opportunities presented by historic timber windows.